+86 10 85323436

+86 10 85323436 ![]() 2022-07-08

2022-07-08 ![]() 5111

5111

Introduction:

Compared to the MSW II this solution is a mechanical sorting with a connected biological drying solution with no biogas production. This is an entry solution to enter into the modern waste recycling which can be flexible extended according to the future market. Our top grade solution for a more harmless utilization of the high organic food waste in China (+55% MSW) and (+70% OFMSW) from separate collected household kitchen waste. After our special sorting the following biological drying and composting BIODEGMA process use the self-heating most effective. As a result, the high amounts of contaminated waste water is steamed out, pathogen food bacteria are killed, organic activity is stabilized, most waste is harmless reduced.

The here shown post-treatment introduce a high potential of plastic recycling. Here the example of PVC removal for a clean “green coal” RDF production. Other plastic recycling (PE PET…) sorting is usable in all our MSW solutions. Additionally, we can use in the near future fertilizer from the OFMWS, closing the environmental circle for a healthier and cleaner living conditions in the cities.

As a result, food waste become a valuable source of its own energy utilization, in a process with no smell or air pollution. Because of that, waste treatment can be treated closer to the collection, saving high cost in China, for long transportation far outside the city (+800 Yuan/t). Part of this savings can go into a better process and compensate the higher land cost. This is the 1st step into modern and cleaner waste treatment in China and future “Urban Mining”.

The waste stream is dried biologically (under use of the self heating) before/after the mechanical processing and reduced by the organic components. The approach of sorting the waste before incineration, in order to recover recyclable materials and separate contaminant, and also to make energy generation from waste more efficient and clean, it's new in China with huge potential.

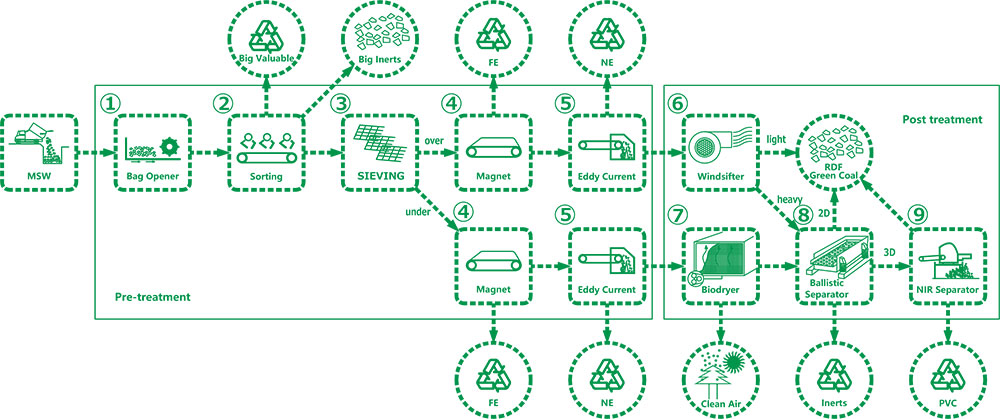

Process Flow Description:

This flow above flow chart is only for your reference. The finest solution depending on the specific waste input MSW or OFMSW and utilization of the output materials requirements at the local area.

1.Our bag opener can open bag in bag waste and spread the waste onto a sorting belt.

2.At the sorting station people and in the future robots remove big impurities (stones and recyclable parts to protect the succeeding equipment (only for MSW).

3.Our special IFE flat screen can sort out finest results with complicated Chinese wet waste, to separate the light materials parts (2D+3D plastic, paper, close with high burning value) “overflow”, from the heavy material (waste food (55%/70%), stones, glass, waste water) “underflow”.

4.Ferrous metals are separated out by magnets (iron, steel).

5.Our IFE ballistic separator reaches finest results to remove nonferrous metals like alloys, copper…and some electronic waste).

6.Our wind shifter is the next sorting process for the light over flow to separate foils (2D) from dimensional (3D) plastics.

7.The mechanical separated organic solids are dried by its internal biological power in our BIODEGMA intensive biological drying process. Steaming out waste water through a biofilter releasing clean smell free air.

8.Our Ballistic separator is a global leader who can separate waste into 3 different parts. A) Underflow small heavy mostly mineral particles, B) 2D plastic foils, C) 3D plastics

9.NIR near infrared can detect specific plastic like PVC and remove it. Because PVC is most hazardous for burners. But also valuables like PE/PS/PP/ABS can be removed for clean reuse and recycling.

Advantages:

1.This is our very effective first step of waste recycling, set for the long term future of deeper city waste recycling recovery and reuse.

2.Harmless better utilization of two main waste factions into

a)green coal (RDF/SRF) 2200 Kcal/kg replacing fossil coal for high energy industry (Cement/Steel)

b)dry stabilized food waste, not pathogen, burnable, landfilled or useful from OFMSW as fertilizer.

3.Free available composting energy can treat largest volume of waste water 55-70%).

4.No air pollution or CH4 pollution from the high volume of organic waste.

5.No bacterial pollution from food waste and no smell pollution at the treatment.

6.First step into the bright waste treatment future easy to add step by step, any kind of additional waste to energy technology or recycling of scarce raw materials.

Please contract us for a deeper talk about the best solution, considering well your regional condition of your project. Call +86 10 85323436

If you are interested to cooperate with us in your region, to develop commercial and technical supported by us waste projects together. Call +86 10 85323436